WYSE: Mechanical Enginnering Day 2 (Birthday!)

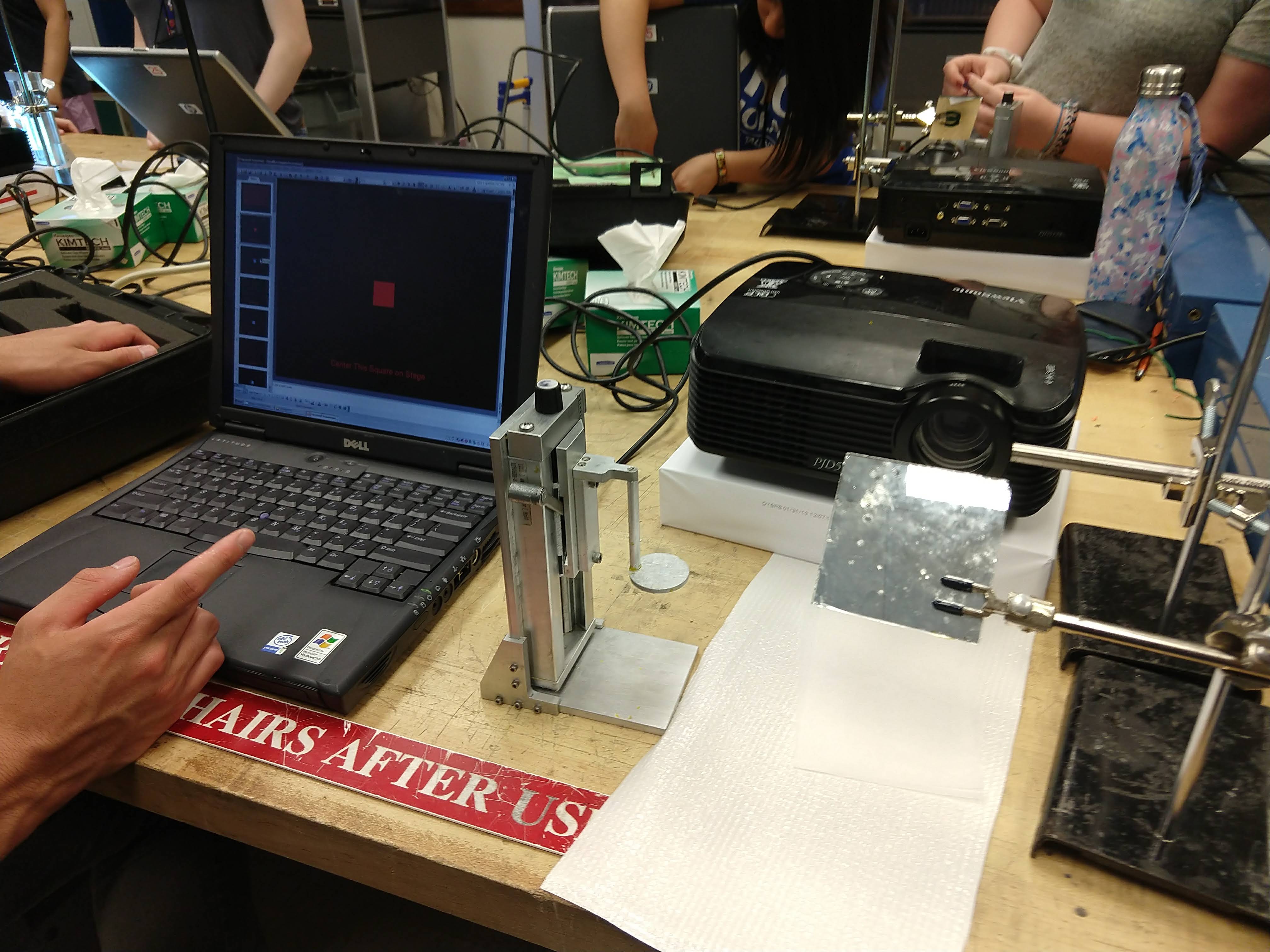

Today was our first day delving into Mechanical Enginnering. We began the day learning about 3D Printing. They explained that we would be doing Stereolithographic (Liquid) 3D Printing rather than the usual Fused Deposition Modeling 3D Printers that we are familiar with. It would be on a much smaller scale, and we went through a demonstration using lenses, mirrors, and a projector to melt liquid into certain shapes. As a stand lowered into the liquid, the more light projected onto the liquid causes it to solidify. (This caused a problem when we accidentally blasted a white computer screen monitor onto the liquid for a half-second; there was already a thick layer developing.)

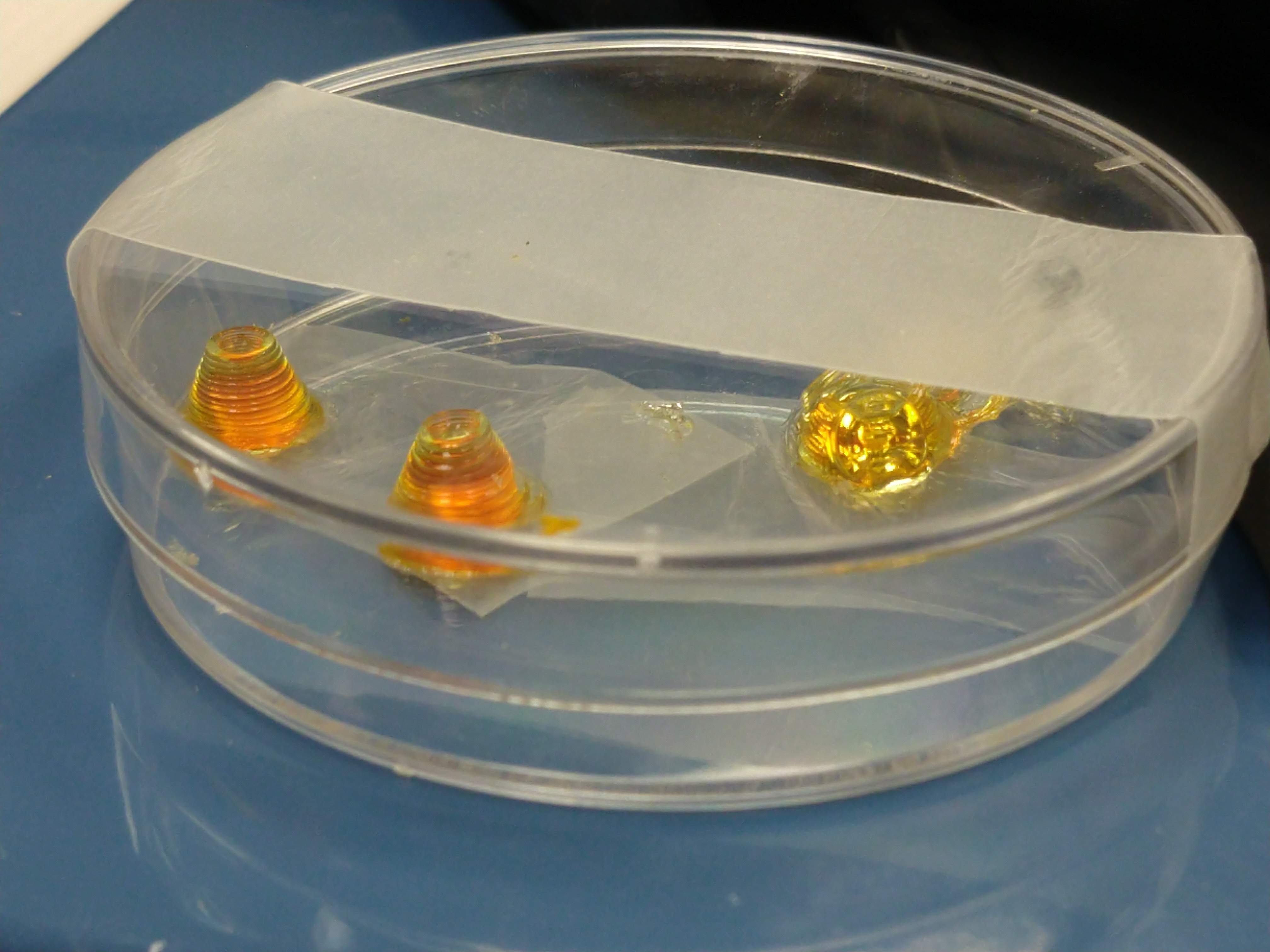

This is what we created! They are supposed to be three flasks, but they ended up flatter than we expected. One of them looks much brighter since the rings developing on the others were lose and had to be cooked before truly solidifying, thus creating a bunch of separate loops suck together on that third flask.

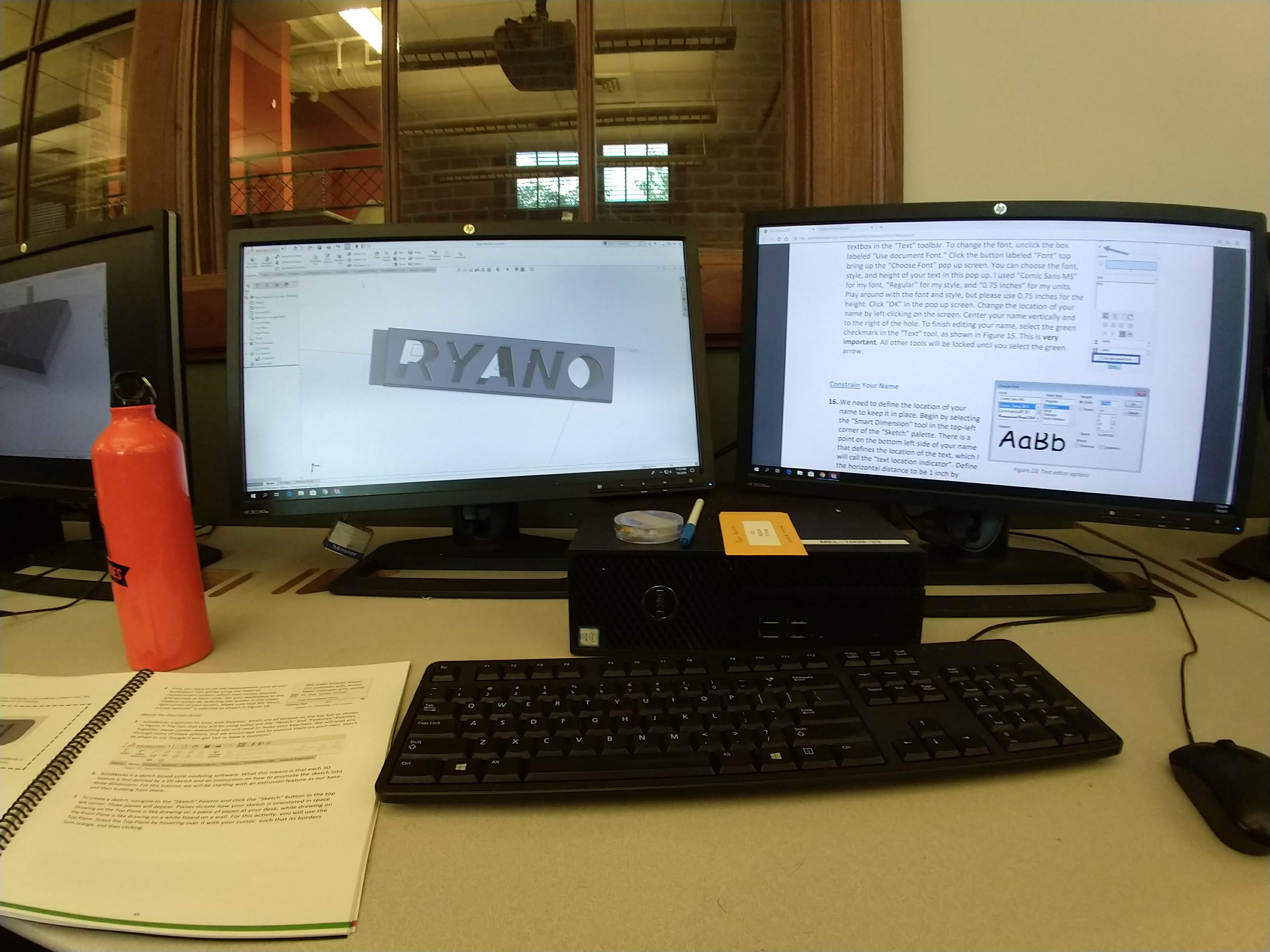

After 3D Printing, we moved onto 3D CAD work! We were introduced to SolidWorks, the CAD program, and began our first project of constructing keychains before lunch.

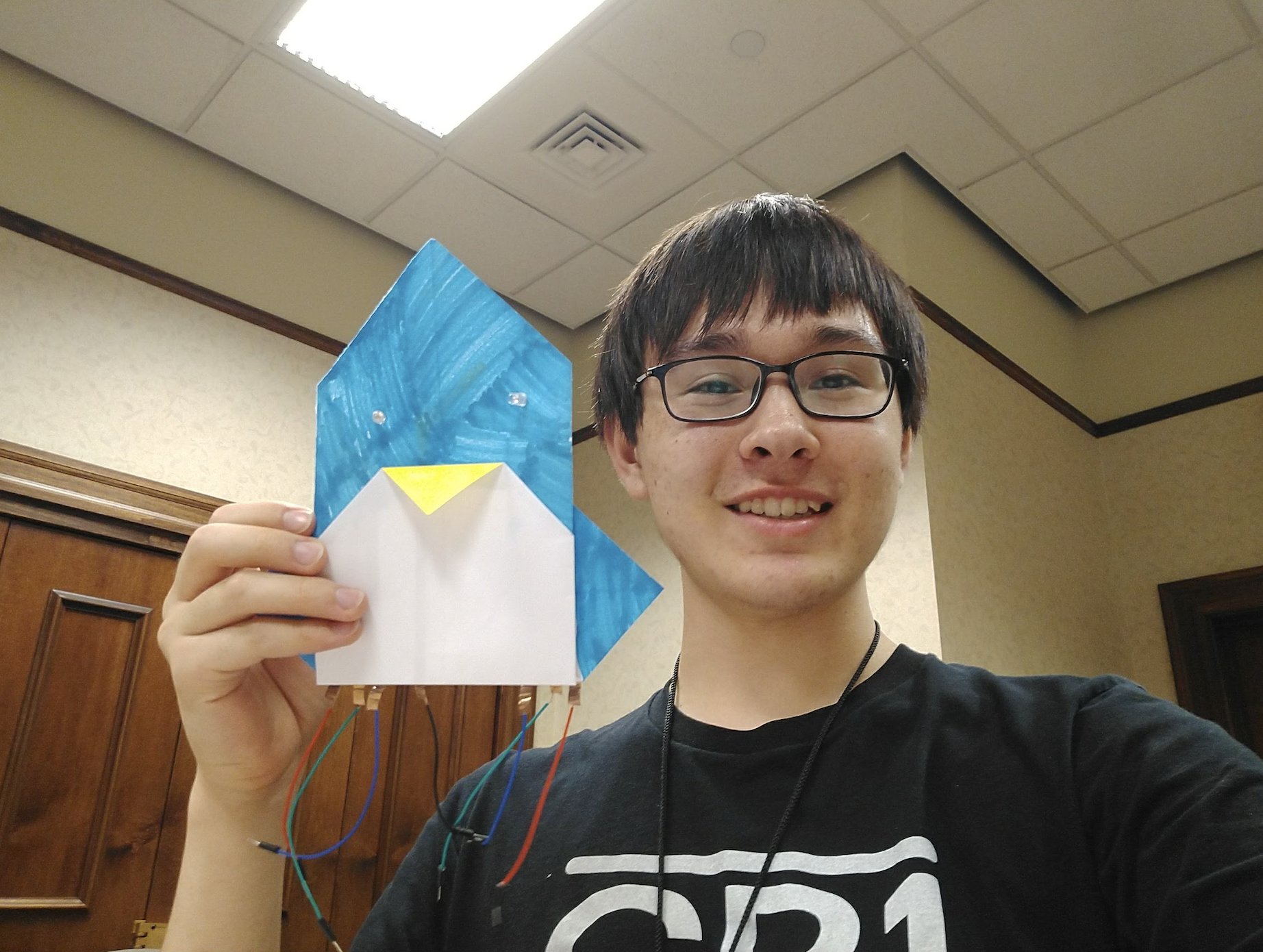

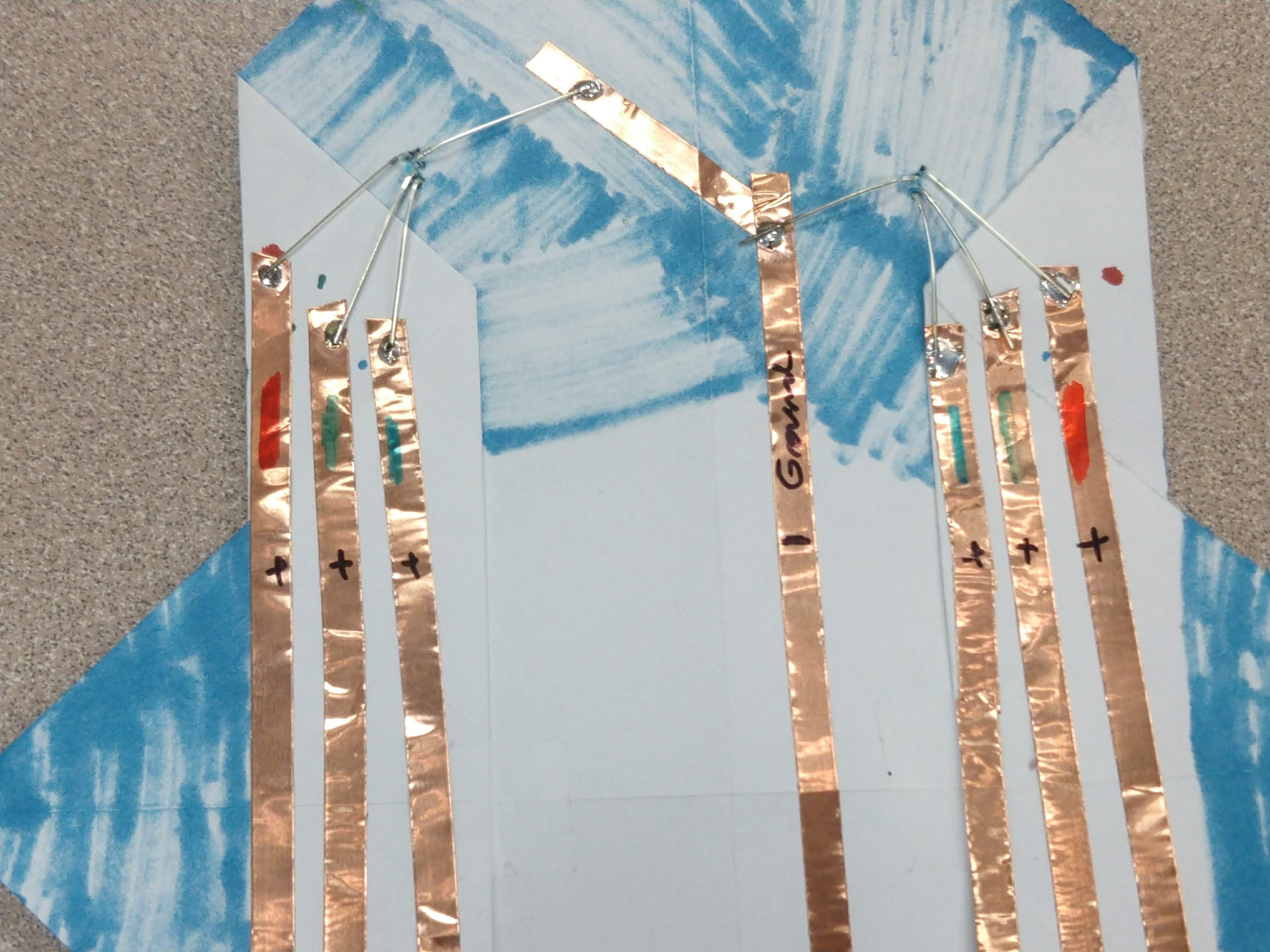

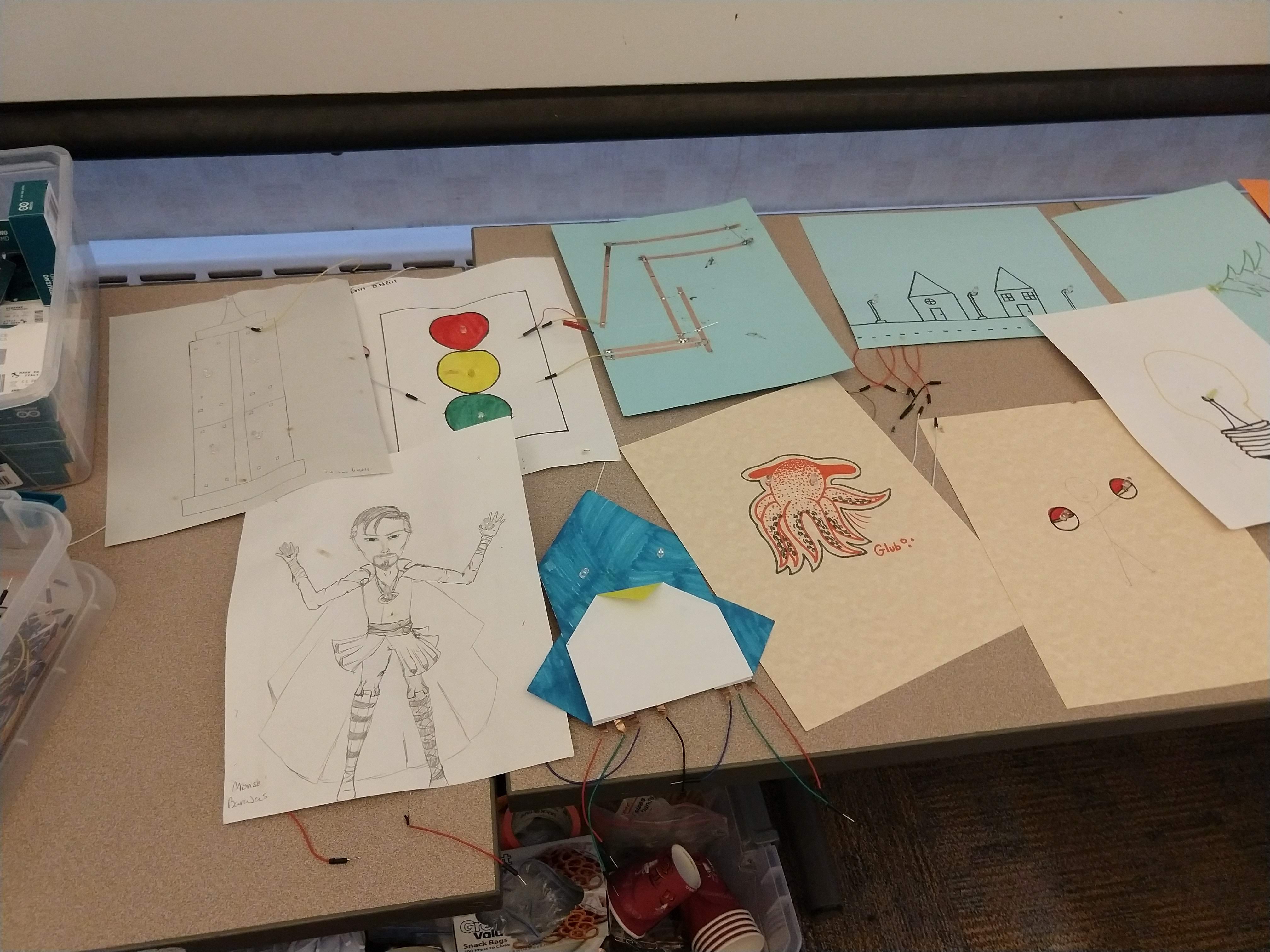

Afterward, we transitioned in groups, rotating from working with Arduinos and wiring to visiting the Micro-Nano-Mechanical Systems Cleanroom Laboratory. First, we are learning about Arduino systems and how wiring using copper tape and soldering works. I’m familiar with a lot of this, so I had the opportunity to try applying R-G-B LEDs and changing how lights light up using Ardunio code. Oh yeah also it’s a cute origami penguin!

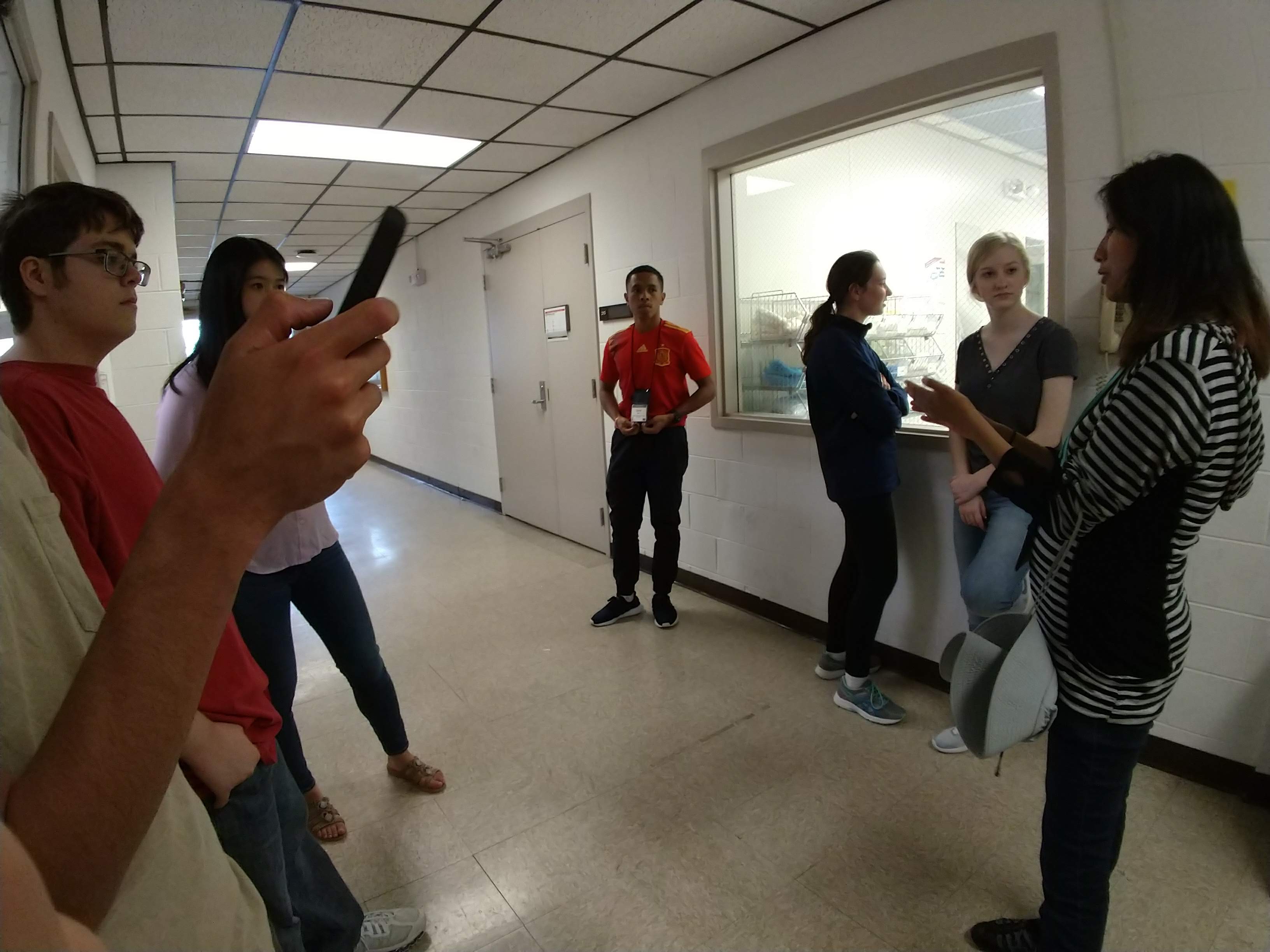

The Cleanroom was quite an experience this time; instead of a simple tour, we were given instructions and a grand demonstration of how each thing worked. The cleanroom is intended to be all clean, and the huge full-body suits are to protect your contamination from the cleanroom, not the other way around. In there, the main production is thin metal or sheets, for example, wafers that will go into phones, this sort of thing can be prototyped here. We followed our own cooking and chemical preparation to turn our own wafer into a souvenir, which actually uses the same method to etch on our camp’s logo as 3D printing does; a smooth layer of liquid is on top, then the logo etching placed on top of the wafer gets in the way of the blue projector light shining down on the wafer, leaving an understandable and high-resolution image on the wafer.

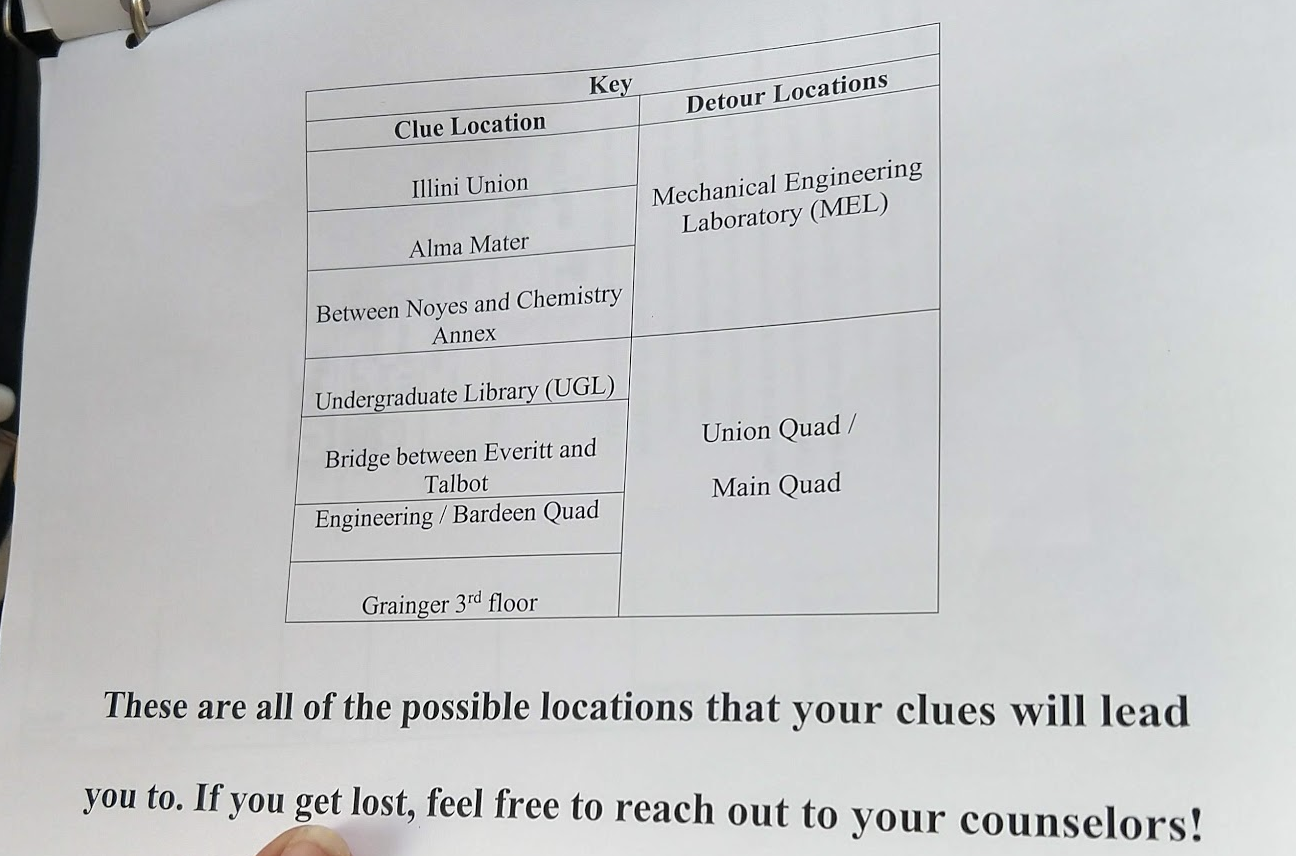

That was about all the engineering excitement from today! We had a scavenger hunt based on clues of locations of certain buildings, for example, the “2-time nobel winner in physics” quads, or an “underground building” referring to the undergraduate library.

And, since it’s my birthday today, I and my dorm friends ate cookies and cake together during dinner, and at the night meeting my birthday was shouted out by Josh and everyone started singing for me. Very cool to turn 17. Now I can fly a plane!

WYSE Posts: